This shop-made belt sander is a great solution for a wide variety of jobs working with metal and wood. The best feature of the belt sander is its simplicity. A 1/3-HP motor drives the 2” x 36” abrasive belt around two wheels. A built-in tracking adjustment and automatic tensioning keep the belt in line. And belt changes take about ten seconds. Homemade Edge Sander Plans Pdf Elmer Verberg's Vertical Wobbler: Elmer's vertical wobbler engine is a two cylinder inverted 'wobbler' style where the motion of the cylinders automatically operates the valves. As soon as you have gotten several simple woodworking projects below your belt, you can readily move on to more difficult projects.

Is Manual Machining Faster than CNC for Simple Parts?

Are you a DIY’er? Are you comfortable fabricating simple machinery? If so, you NEED a decent belt grinder, preferably in the 2″x72″ belt size. You’ll find a thousand and one uses for it once you put one together, and it’s very easy to put one together. This page is all about the resources and ideas you’ll need to plan your own belt grinder project.

Belt Grinders are great for blending smoothly flowing shapes, deburring, and generally improving the look of parts. For the latter, you also want to make sure the surface finish of your other machining processes is all that it can be. Check out our guide to Milling Machine Surface Finish Tips for some ideas.

Bill Pace grinder has been made by several on the HSM boards.

Shows tracking mechanism at the top very well…

Platen inspired by Lane added to Bill Pace’s grinder…

More on the tracking mechanism by George Barnes…

Lane over on HSM built one along the same design…

Andrew McLurkin’s Bader III is mounted on its side to make it easier for him to do fine work. Note the very small wheels and wrap around tool rest so he can get inside tight areas.

Dozier makes some of the best grinders there are. This series shows off the different accessory configurations they have available:

Here is the grinder. Note the pneumatic tensioner.

3 Configurations, left to right: the basic wheel, slack belt grinding, and a platen grinding setup…

Beaumont Metalworks offer the excellent KMG grinder:

It would be nice to turn this grinder horizontally like McLurkin shows at the top of this page and then use this attachment with a rest that fit nicely. You could really get into some tight spots with it!

Tooling arm rack is a clever accessory that makes changing the configuration fast and easy.

Here is the grinder sporting a platen attachment, and a rest on the lhs photo. Note the solid CNC construction. Minimal welding. Picture on far right is the slack belt attachment.

Or, how about a rotary platen?

Seems like it could take the place of several of the other accessories. The actual “platen” is a rotary belt under tension with rollers.

Here is a variable speed JL grinder:

The venerable Bader III grinder is well respected:

Big Belt Grinder Links Page Best of Links:

Mike Alexander’s Belt Grinder: Easy to construct 3-wheeler

Emerald Isle’s KMG Copy…

Great looking kit by Simplatic. Looks like a good plasma cutting job…

Fogg’s PDF Plans for a KMG Clone…

Check out the “Dream” KMG attachment, pretty cool!

The rest is slightly reminiscent of the “Dream” KMG rest shown above. The Wilmont is a nice variation on the KMG and the site includes plans for a home shop model you can build.

It has 5 interchangeable contact wheels that can be indexed into position–these 3 plus the other 2 corners of the triangle have larger wheels…

They also make a hollow grinding attachment that’s pretty neat…

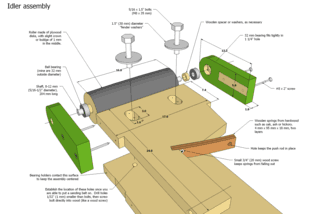

Below I have included some drawings and models that should hopefully help you with the dimensions and hole layouts. I included the drawings as pdf's and the .step file for the entire assembly so you can see how it all fits together. If you do not have a 3D modeling software I have also included a 3D pdf that will anyone with adobe acrobat (its free) to be able to view the assembly as well.

Note: While making this I made some changes and these drawings and models are not 100% the same as what I show being made. I will address the changes in each step as they differ from the drawings.

Material List:

2in x 2in square tubing in the following lengths:

One 5in long tube

Two 10in long tubes

One 11in long tube

1.5in x 1.5in square tubing in the following lengths:

One 7in long tube

One 17in long tube

One 12in long tube

Two pieces 2in x 6.5in x .25in (this can be thinner but it is nice if it is thicker because it will be threaded)

Two pieces 4in x 4in x .125 (this can be thicker if you want but not any thinner)

Four 2in long pieces of 2in angle iron

One piece at least 2.5in x 8in x .25in for the tool rest

One piece 2in x 2in x .25in (I made mine more around 2in x 4in x .25in which you will see later)

One piece 1.5in x 1.1in x .375in for one half of the hinge

One piece 2in x 2in x .375in for the other half of the hinge

Homemade Belt Sander

Parts list:

Lots of bolts (each step will show the bolts you need, most are 3/8in bolts but they don't have to be)

Lots of lock nuts (these are important as this vibrates a lot and you don't want it coming apart)

Belt Sander Plans Free

Two adjustable position handles (I used these 3/8 x 1 1/4 ones)

Homemade Belt Grinder Plans Pdf

Flat platen tool (I bought this one but the second link I provided has the plans for one if you can make it)

Guide, tracking, and drive wheels (I bought mine form here but the third link shows how you can make your own)

A gas spring (I used a 7in 100N/22lb spring from amazon but it is no longer available)

A handle (I turned a 2 x 2 piece of wood into a handle but you could buy whatever you want)

A motor (This completely depends on what you have or the power you want, I have a 1hp motor with a vfd to provide variable speed control)

Comments are closed.